Analysis of Main Engine Performance Decline in MV. Meratus Medan 1

DOI:

https://doi.org/10.30649/baitaengineering.v2i1.23Keywords:

Main Engine, MV. Meratus Medan, Ship SpeedAbstract

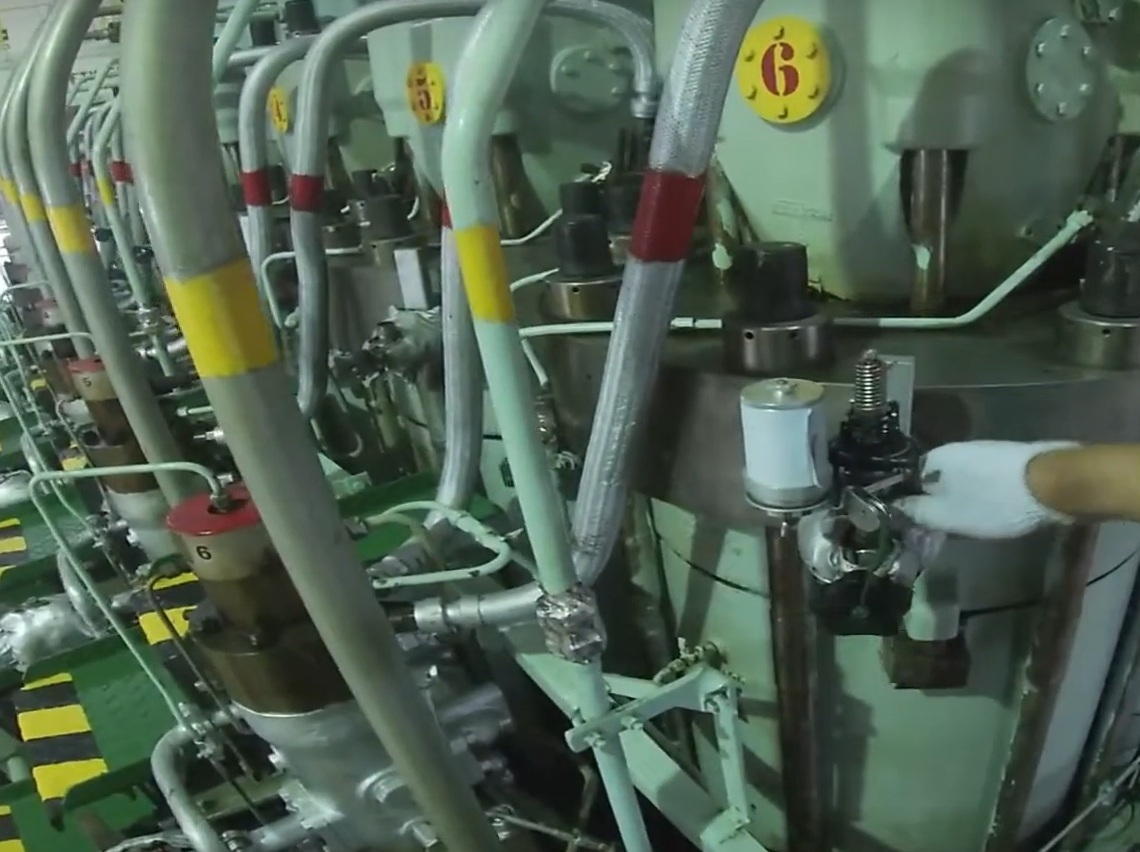

The time used by researchers to conduct research for one year, on the MV.Meratus Medan 1 ship. MV.Meratus Medan 1 ship is a Container Ship built at Imbari HIP Building, Japan in 1996. The MV.Meratus Medan 1 ship is a ship owned by the shipping company PT. Meratus Line which is headquartered in Surabaya. This research method uses a qualitative method using a descriptive approach and the data collection techniques are interviews, photo and video documentation, surveys and observations. The data sources used are using primary data and secondary data. Primary data sources are obtained from direct interviews with several crews, while secondary data sources are obtained from books, journals, web and others. The results of this study indicate that the factor of decreased main engine performance is caused by not paying attention to the running hours or working hours of the main engine. The impact caused by the factors that cause a decrease in the performance of the main engine is that the ship is difficult to manoeuvre berthing at the Port of Dili, Timor Leste. Efforts are made to overcome these problems by overhouling replacing broken piston rings with new ones on cylinders 2, 4, 5, 7.

Downloads

References

Arifin, M. J. (2020). Analisis Patahnya Piston Ring Pada Mesin Induk Di MV. KT 05. 56-57.

Banu, Pradipta (2023). Analisis Penyebab Kebocoran Jacket Cooling Main Engine di MT. KLASOGUN. 36.

Bosch, Robert (1972). Distributor Type Diesel Fuel Injection Pumps Motor Diesel. Jakarta: Pedoman Ilmu Jaya.

Hidayat, R.T. (2020). Optimalisasi Kerja Inert Gas Generator Guna Menunjang Kegiatan Bongkar Muat di Kapal MT. Success Dalia XLVIII.

Jufri, M.F. (2021). Analisis Kurang Optimalnya Kinerja Bosch Pump Bahan Bakar di MT. Michiko. Vol 5 No 1.

Karyanto, E. (1986). Teknik Motor Diesel : Perbaikan, Penyetelan, Pemeliharaan, Troubleshooting. Jakarta: Pedoman Ilmu Jaya.

Kurniawan, A. B. (2023). Pengaruh Retaknya Cylinder Head No.2 Terhadap Turunnya Daya Mesin Induk 2 Tak di MT. Gas Soechi 28. 11.

Nazir, M. (1988). Metode Penelitian. Jakarta: Ghalia Indonesia.

Prasetya, Tristanto (2018). Keausan Crank Pin Jounal Crankshaft Pada Diesel Engine Generator Di MV. KARTINI BARUNA. Vol 9 No 1 9(1), 2126-2136.

Siahaan, J.L. (2022). Analisa Kekerasan Bushing Connecting rod Menggunakan Bahan Paduan Aluminium Dan Bronze Dengan Sistem Perlakuan Panas Pada Mesin Mobil L300 Diesel. ISSN: 2598-3814. Buletin Utama Teknik Vol. 17 No. 3.

Sugiyono. (2018). Metode Penelitian Kuantitatif, Kualitatif, dan R&D. Bandung: Penerbit Alfabeta.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 BAITA Engineering: Journal of Naval Architecture and Marine Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.