Physical and Mechanical Characteristics of Welded Joints Friction Stir Welding (FSW) AA 5083 with a Variation of Rotational Speed Probe

DOI:

https://doi.org/10.30649/baitaengineering.v2i2.41Keywords:

Keywords: FSW, AA 5083 butt joint, rotational speed, physical and mechanical properties, probes.Abstract

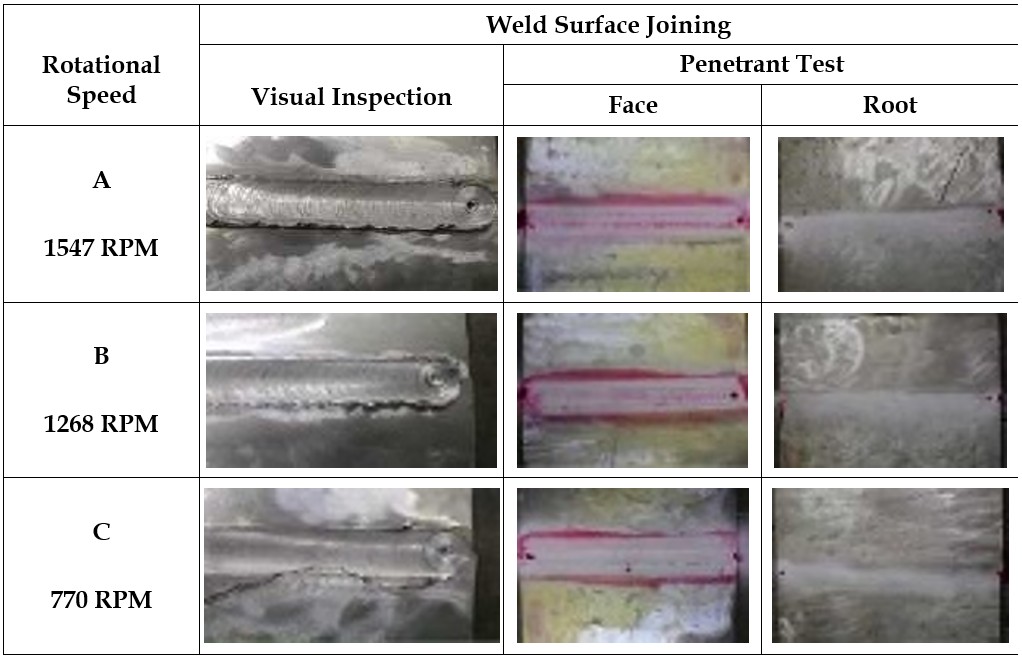

Friction Stir Welding (FSW) is a welding process in which a new environmentally friendly has a good quality of welded joints. FSW also does not require filler metal. The process of FSW quite simply by utilizing the friction between the stationary workpiece by moving the workpiece. Friction second workpiece can generate local heat can soften the part. This is done in a state of solid state joining. FSW application usage is common in the aluminium alloy. Aluminium is often used in shipbuilding are AA 5083. In this study, analyzing the physical and mechanical properties of welded joints results with welding speed of 36 mm/min and a variety of probes rotational speed 1547 rpm, 1268 rpm, and 770 rpm, Standard testing using AWS B.4 2007. The results showed no indications of defects occur when tested of penetrant, either face or root. However, on a macro-etching test of defects found kissing bound and worm holes at 1268 rpm rotational speed variation and defects are found only worm holes in the variation of rotational speed 1547 rpm and 770 rpm. Values of tensile strength and buckling strength is best at 770 rpm rotational speed variation value (203.247 MPa or 20.725 kgf/mm2; 33%) and (30.1288 Kg / mm2; 49%).

Downloads

References

Ghozali, Imam. 2005. Application of Multivariate Analysis with SPSS program, Diponegoro University Press, Semarang.

Haver, Van, W., 2007. Friction Stir Welding. BWI. Belgium.

Uk, twi 2016. Schematic Friction Stir Welding. Retrieved February 2016, from twi: http://www.twi.co.uk/fsw/.

Wijayanto, Jarot & Anelis, Agdha. 2010. Effect of Feed Rate on Mechanical Properties on Friction Welding Stir Welding of Aluminum 6110, Journal of Engineering Competence Vol. 2, No.1, November 2010.

Wijayanto, Jarot., 2012. Effect of Feed Rate against the mechanical properties of aluminum friction stir welding. Banjarmasin State Polytechnic.

Y. N. Zhang, X. Cao, S. Larose and P. Wanjara. 2012. Review of tools for friction stir welding and processing. Vol. 51, no. 3. Canada.

Published

How to Cite

Issue

Section

License

Copyright (c) 2025 BAITA Engineering: Journal of Naval Architecture and Marine Engineering

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.